Certifications & Quality Policy

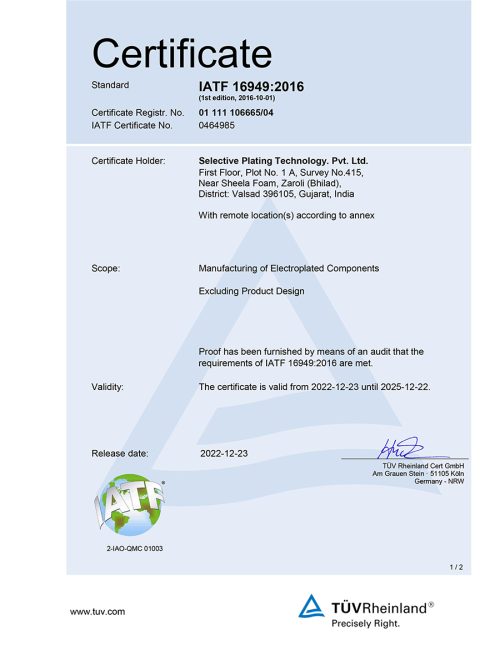

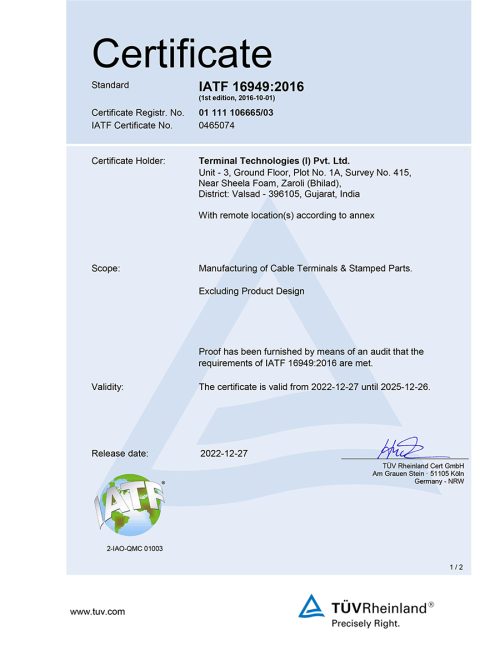

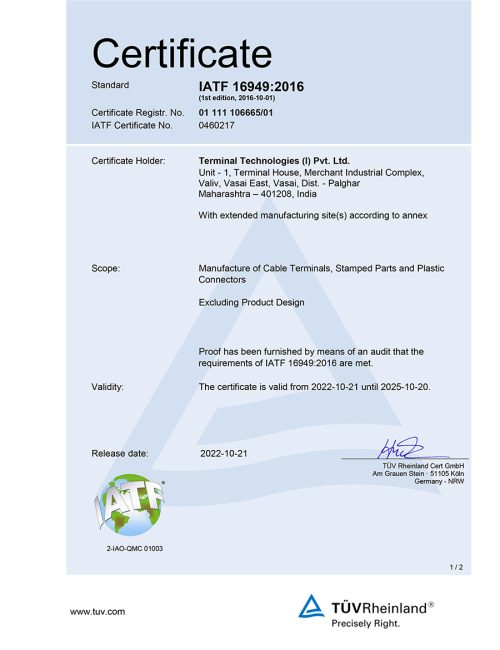

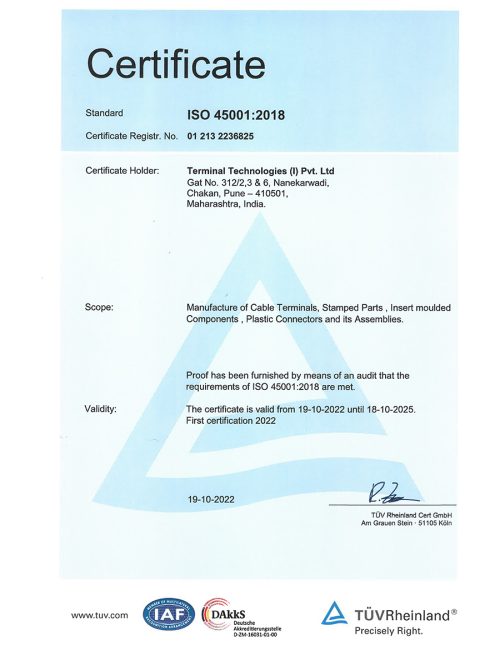

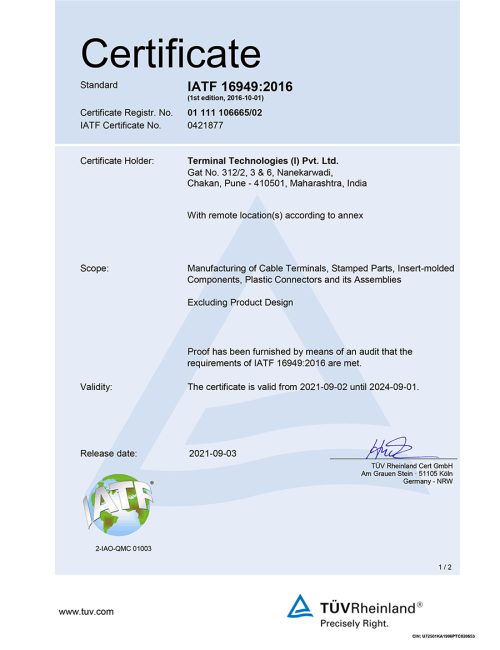

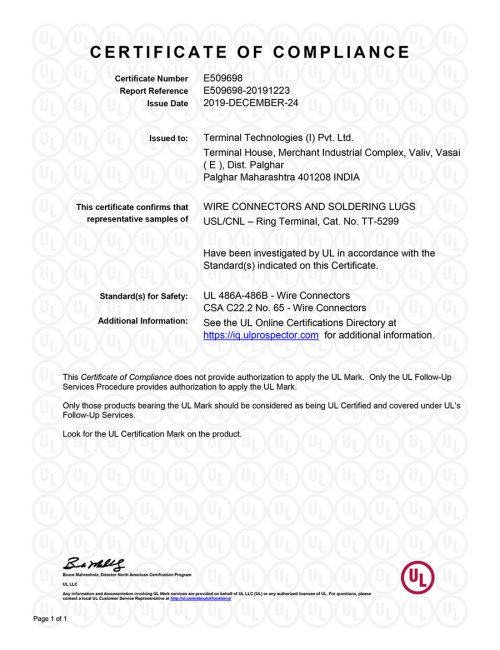

All TT plants are certified for IATF 16949 systems and select units are certified for ISO 45001 & ISO14001.

Select product lines are UL and CE certified for meeting the stringent US/EYU applications.

Quality

IOT implementation to increase efficiency

With the connected world offering solutions at the palm of your hand, TT is investing in ways to connect most of its production and tool room machineries for key parameter monitoring.

All of those machines will be connected and monitored for OEE, availability, target achievement and efficiency monitoring. The entire data will be available to the senior team for timely actions. Many online inspection cameras are being installed on high speed stamping and moulding lines to monitor the key parameters based on 24-hour real-time data.

Modern Testing & Validation Centre

The Testing & Validation Department operates in compliance with the ISO8092 ‘Road vehicles – Connections for on-board electrical wiring harnesses – Part 2’. The data is obtained and evaluated as defined in the international and commercial standards.

The Testing center are equipped with:

- Vision Measuring Machine Stations

- Micro Hardness Tester Stations

- Mitutoyo CNC CMM Stations

- Fischer scope XRAY XAN 250

- Vibration Test Chamber with Hot & Cold condition

- Thermal Shock Chamber

- Dust Test Chamber

- Water Test Chamber

- All Standard Electrical Testing Instruments

Quality Objectives

The company will strive to achieve complete customer satisfaction by producing and delivering products that match specifications for performance parameters by total involvement of human input and continual improvement of procedures and resources

Our Quality Objectives

To maintain the quality levels of incoming raw material and output at prescribed levels by proper controls and systems.

To involve the employees fully into quality systems, to develop a quality culture for continuous quality output through training and suggestions for improvement.

To strive to minimize the customer complaints about quality and services.

To ensure that the company’s products are meeting the necessary national international customer specification to performance parameters.